The ST technology removes organic and inorganic contaminants from soil. Electrolyte is passed through contaminated soil using electrokinetics and hydraulic pressure. An electrolyte “recipe” is developed for each site through lab tests. Reliable removal of contaminants is assured.

The system is transported to contaminated sites and is self-contained. Decontamination occurs ex situ. Highly concentrated spent electrolyte is shipped offsite.

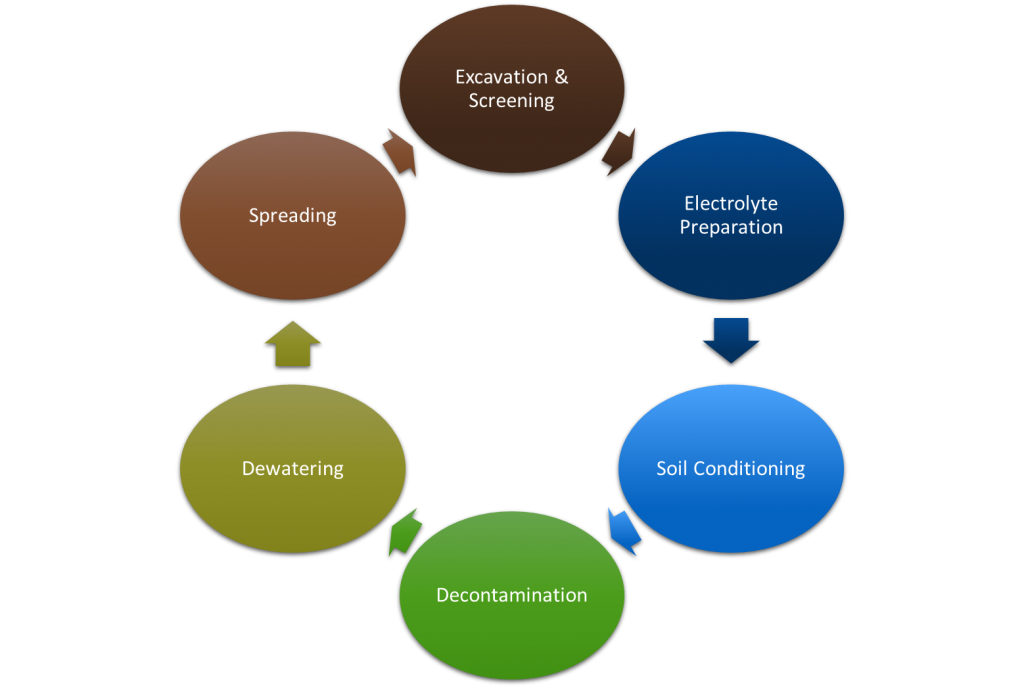

Decontamination involves the following steps:

- Contaminated soil is excavated screened to remove large rocks and debris.

- Customed-designed electrolyte is prepared on site.

- The screened soil and electrolyte are mixed to produce a slurry.

- The slurry is passed through the decontamination unit where contaminants and excess electrolyte are removed.

- The decontaminated soil is replaced in the original excavation.

- Spent electrolyte is concentrated with the permeate being reused and the concentrated contaminants being sent off site for treatment/disposal.

The decontamination unit comprises two chambers:

- In the decontamination chamber, electrolyte is passed through the slurry.

- In the dewatering unit, residual electrolyte and contaminants are removed yielding a decontaminated paste.