This time-lapse video provides an illustration of the dewatering process at the lab scale.

327 Hour Time Lapse Video

In 2019 EKS commissioned a 1,700m3 large scale field test in Vegreville, AB.

The purpose of this test was to prove the scalability of our technology. EKS requested “the worse of the worse” tailing, which industry provided. Our tailings had an SFR (Sand-To-Fines Ratio) of <0.05! Anyone can dewater coarse particles, but few can dewater fine particles economically in a timely fashion. The results of this field test showed:

- The economics and dewatering rate of our process improves with scale

- Our process smashes existing competing technologies from a governance, economical and environmental perspective (as supported by a detailed LCA)

- As expected, our process performs extraordinary well when used on fine tailings

Past lab research have answered the following research questions:

- Dewatering behaviour at high % solids (>50%)

- Optimisation of energy consumption

- Anode conservation

- Impact of fines content

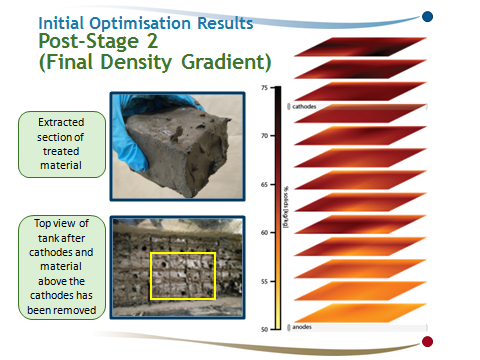

- Control of densification patterns

- Improving dewatering predictability

Results from this program have already answered some of important questions.

- The ability of the technology to dewater to greater than 65% solids has been proven through repeated tests.

- The process can be controlled to produce uniform vertical and horizontal density gradients eliminating the potential for soft spots or off-spec product.

- The EKS forecasting system used for engineering design and system operation purposes has been empirically validated.

- The energy efficiency of commercial-scale systems id forecast to be comparable or better than with small-scale tests.